Today I got a lot done on the foundation work for the 60m tower. I finished up the boom struts for the 15m yagis and the 17m yagi. I made a form for the bottom plate measuring 1.2×1.2m and the rebar cage as well. The gravel in the bottom of the pit was evened out and is about 20-30cm thick. Tomorrow I will hopefully get enough done so that I am able to pour the concrete either tomorrow evening or on Saturday, we will see…

Monthly Archives: July 2014

Working on the 60m tower foundation

Vacation update

I have been sloppy with the updates during the vacation. I have been keeping myself pretty busy and with the intense weather we’ve had this summer (around 30C most of the time) the tempo has been slow even though I’ve been trying and think we’ve gotten a lot done. We are not used to these kind of temperatures but it’s funny how the body slowly adapts to it. One evening I was feeling cold and put my t-shirt on and when I checked the temperature it was +25C 🙂

A new ham, SA2CHQ came by to visit and said he was able to powder coat at work. So he got to powder coat the guy wire rings and the result was great! It’s fun with some new blood and he lives rather close. We also have another ham, SA2CLC who is a skilled young guy and lives not even 5km from here. He came by yesterday and helped to move some gravel with his old tractor, so now I can soon pour the concrete.

SM2UVU also came up and stayed a couple of days, and we fixed the broken tower section together and he had also modified some washers used for the guy wire rings. Now those sections are also ready. The only thing needed now is to get the fixed tower section galvanized and at the same time I will hand in the boom struts.

It was also very fun that Femma and Aloys (PA3DWK, PA3DAT) stopped by for the third time. They love to travel through Scandinavia and last time they were here was three years ago, and quite a bit has happened since then. They are truly great people and interesting people so it is always a lot of fun. Aloys was hoping to help me out quite a bit but because of not having all material we were a bit limited in what we could do. So we cleaned up a bit, moved some guy wire lines down to the barn etc. But it was so warm anyway that it was hard to work.

Project progress

On Monday my vacation starts but I’ve been down at SJ2W during this week as well, since I didn’t really have any work that I needed to be at the work QTH. So I’ve been mixing real work with own work and have gotten some various stuff done. Also had a few visitors SA2CLC and SA2CHQ that both live very near the station and are two very eager new hams. SM2UVU came up with the welding jig he built when welding his 45m rotatable tower and also some other material so I can fix the top section that the forest machine broke.

I’ve also done some ventilation work for the shack so that we force the warm air from behind the “fake wall” down to the basement. It really made a huge difference on the air in the basement that went from typical moist basement air to a really nice and comfortable environment instead.

I also welded the attachments to the guy wire ring that SM2UVU got for us last year. I added some extra tabs where we can attach lines for the future 160m 4-SQ and some possible link antennas. Tomorrow SA2CHQ will pick them up to get them powder coated.

This weekend it’s the IARU contest and we will be on 20m SSB as SK9HQ plus also on 10m sharing with SK3W both CW/SSB to cover most openings if we get sporadic E etc. We might also do some lowbands since we didn’t get enough participants for serious efforts on all bands. So when 10m is closed we might be on 40 as well.

Machining work

Last weekend I spent some time at the station again with my girlfriend. I cut down some trees that were left standing earlier and also a lot of small trees that had grown up rapidly. I will need to take a few more trees down since I decided to move the tower down a bit on my land to make the most out of it.

I also did some minor modifications on the welding cart and painted it so now it’s finished.

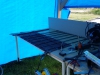

I have also been machining a lot of parts, check the pictures and comments on them for more information.